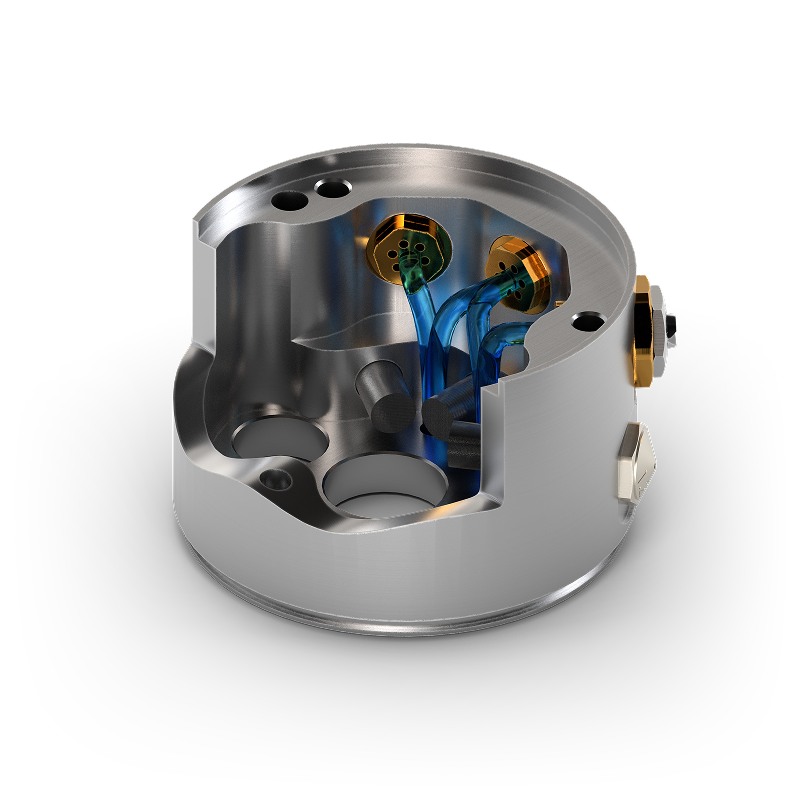

Head design

We used 3 different mechanisms to prevent icing. The built-in heater, the use of the heat of the water, which fills the entire volume of the head, and the appropriate geomertia of the head protect the device in the most adverse conditions.

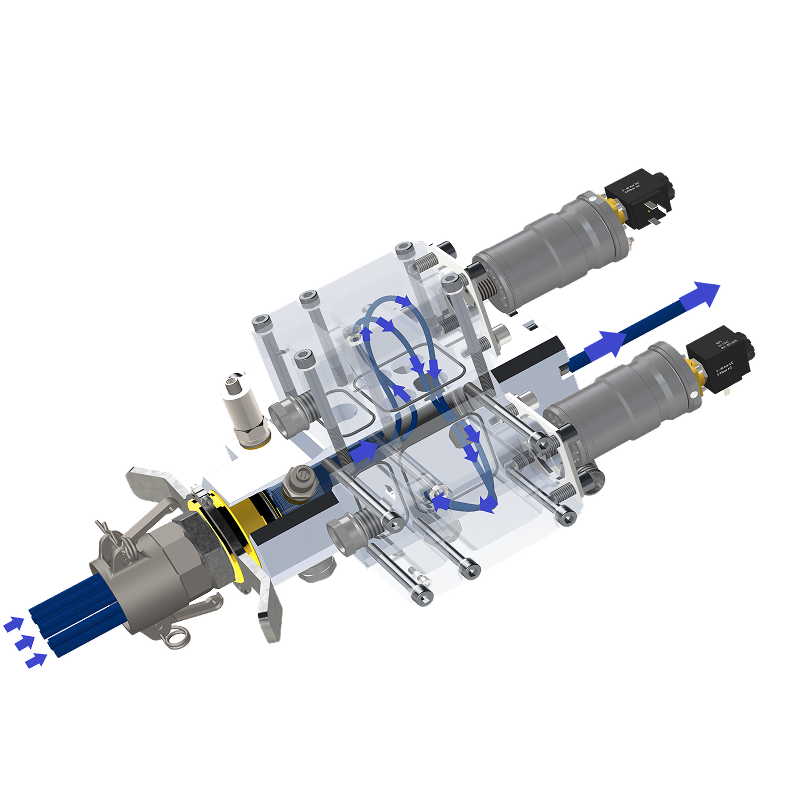

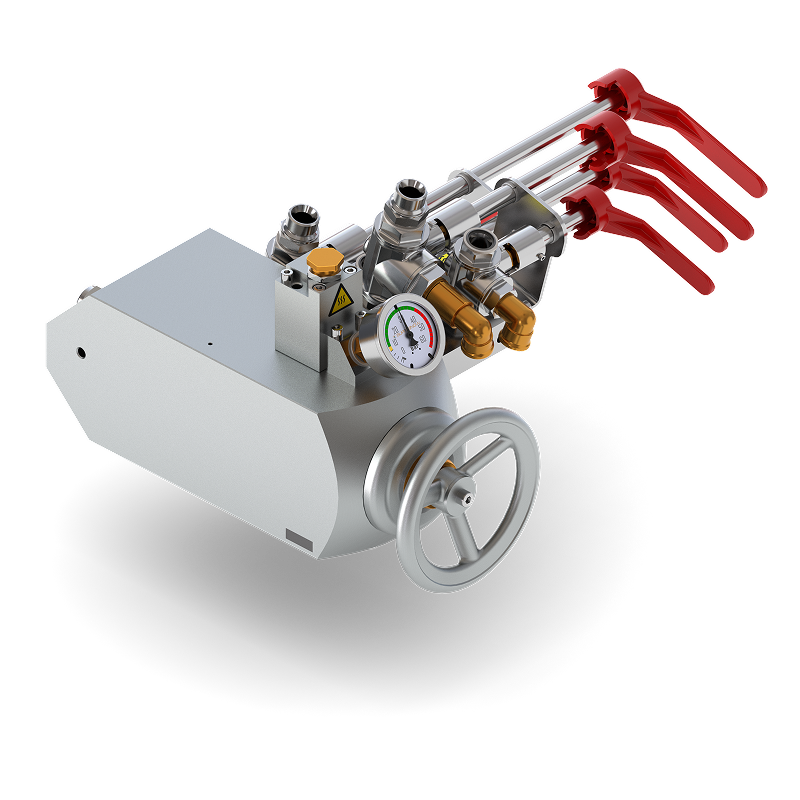

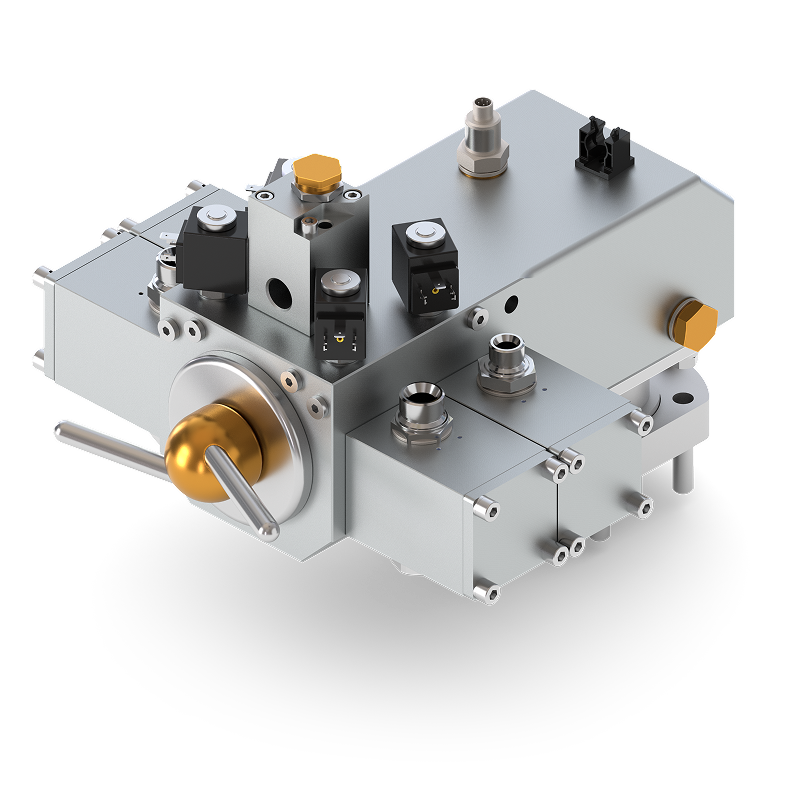

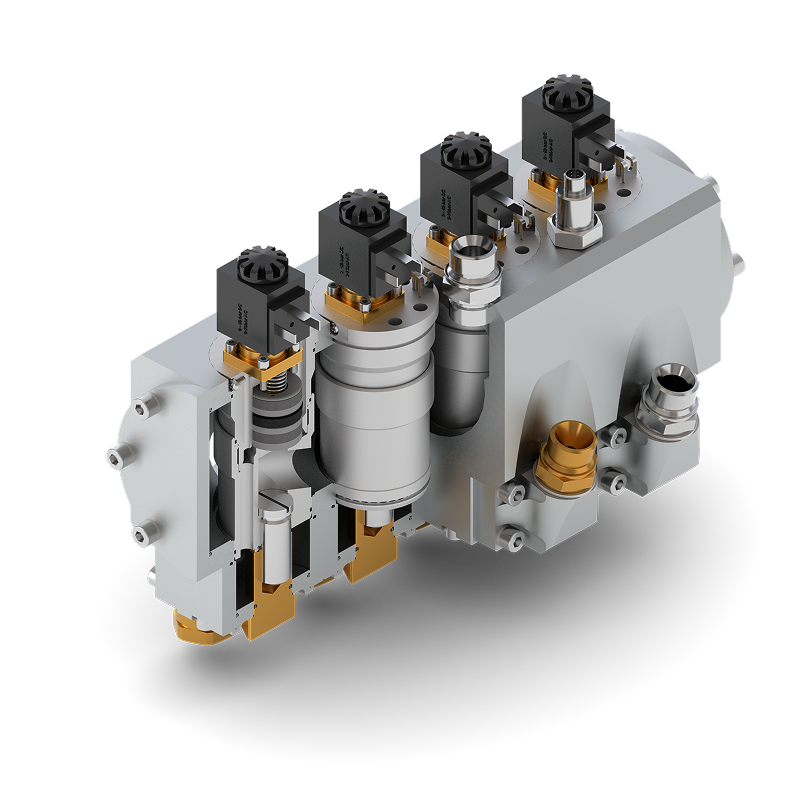

Water complex

The water unit uses the energy of flowing water. This heats its components, including water valves, which prevents icing and extends the life of the system.

Nucleation nozzles

A self-cleaning system for nucleation nozzle filters via inlet holes takes any impurities into the water nozzles, protecting the filters and nucleation nozzles from contamination. This process reduces the amount of maintenance required.

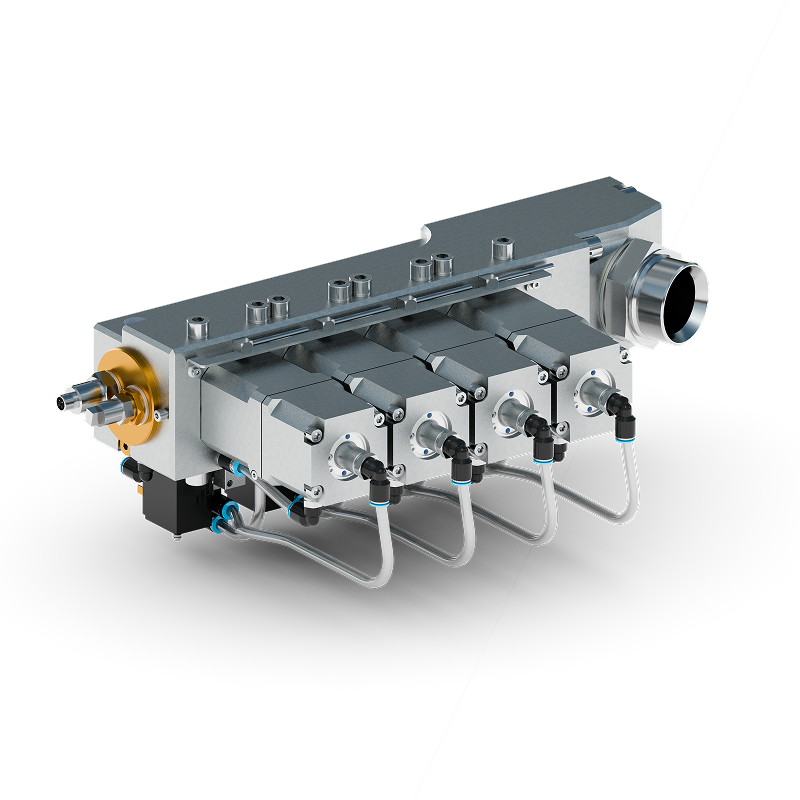

Water valves

The lance uses water directly from the pipeline to heat the body, and its pressure is used to control the valves, reducing electricity consumption.

Nucleation nozzle

The new design of the nucleation nozzle allows snow production as low as -1.5°C wet thermometer, using less than 2 kW of electricity. VIRGA’s maximum output is achieved even at -7°C, without adversely affecting the unit’s operating economy.

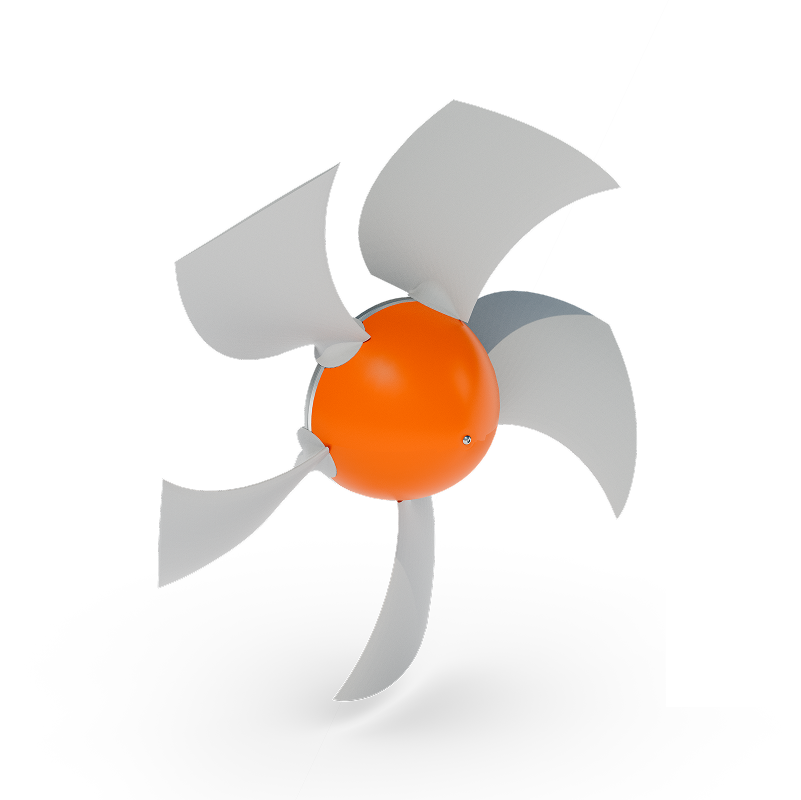

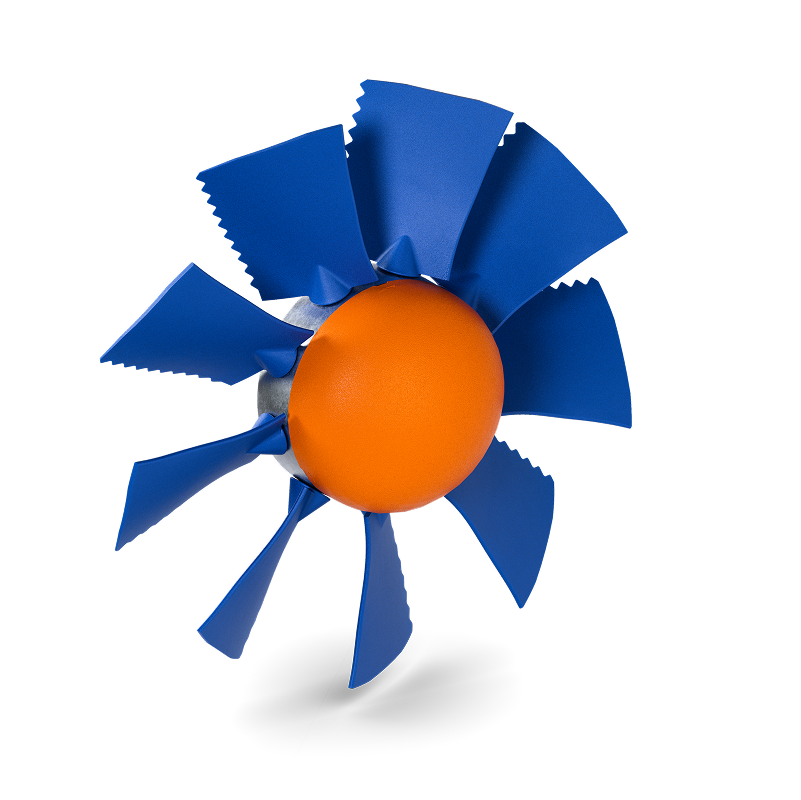

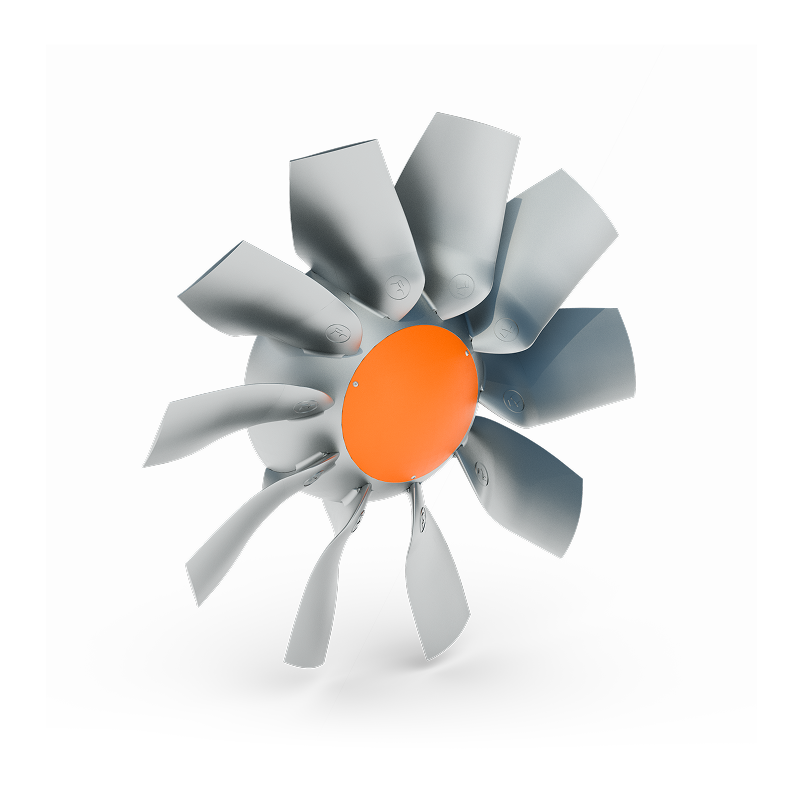

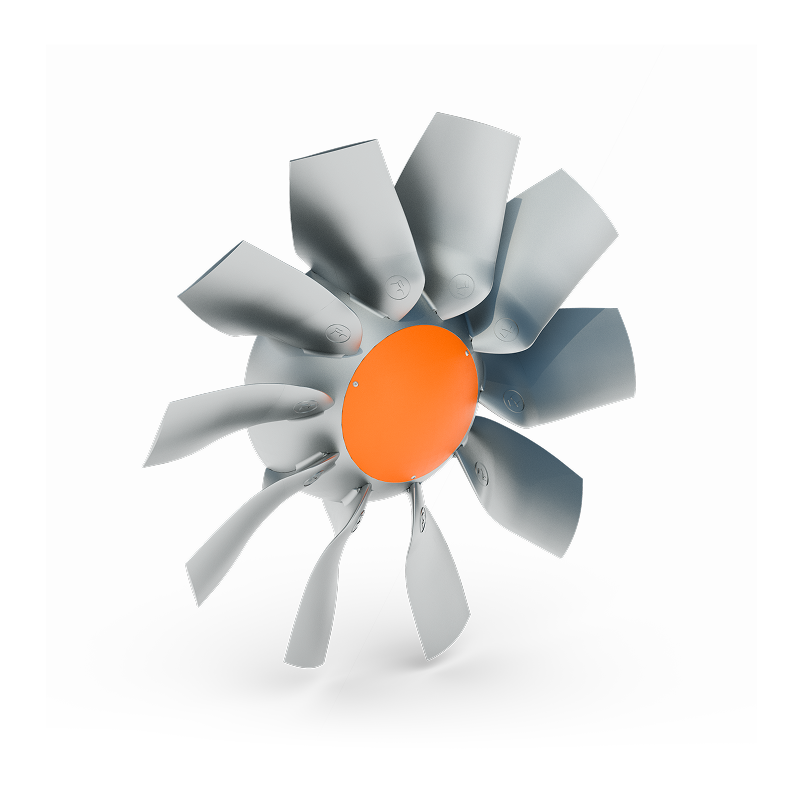

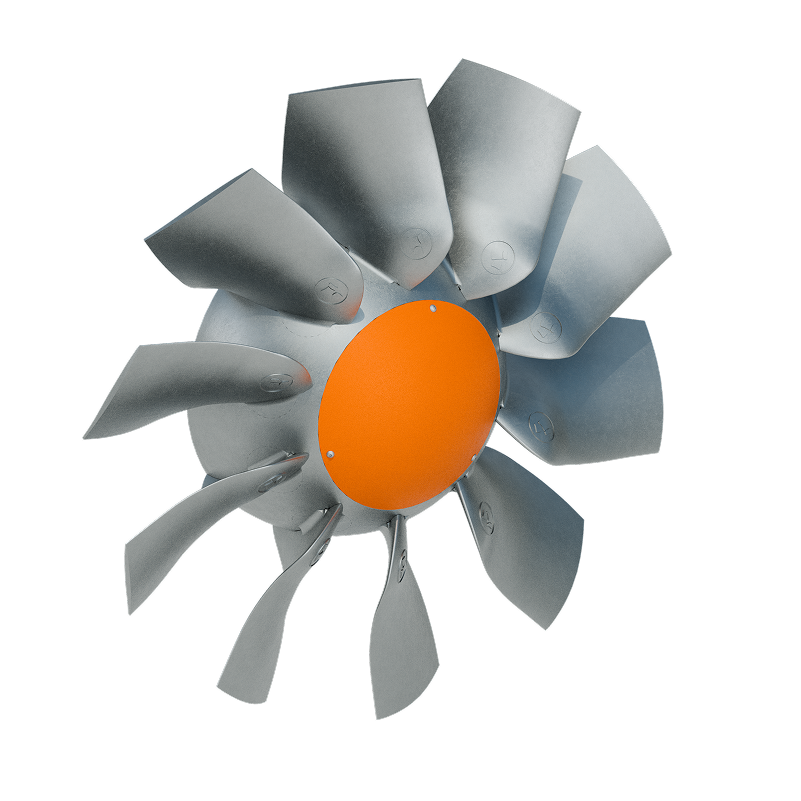

Fan

The 600M boasts a low noise level, which benefits both the surrounding nature and the comfort of operators. The ultralight design, weighing only 545 kg, makes it easy to transport and streamlines the snowmaking process.

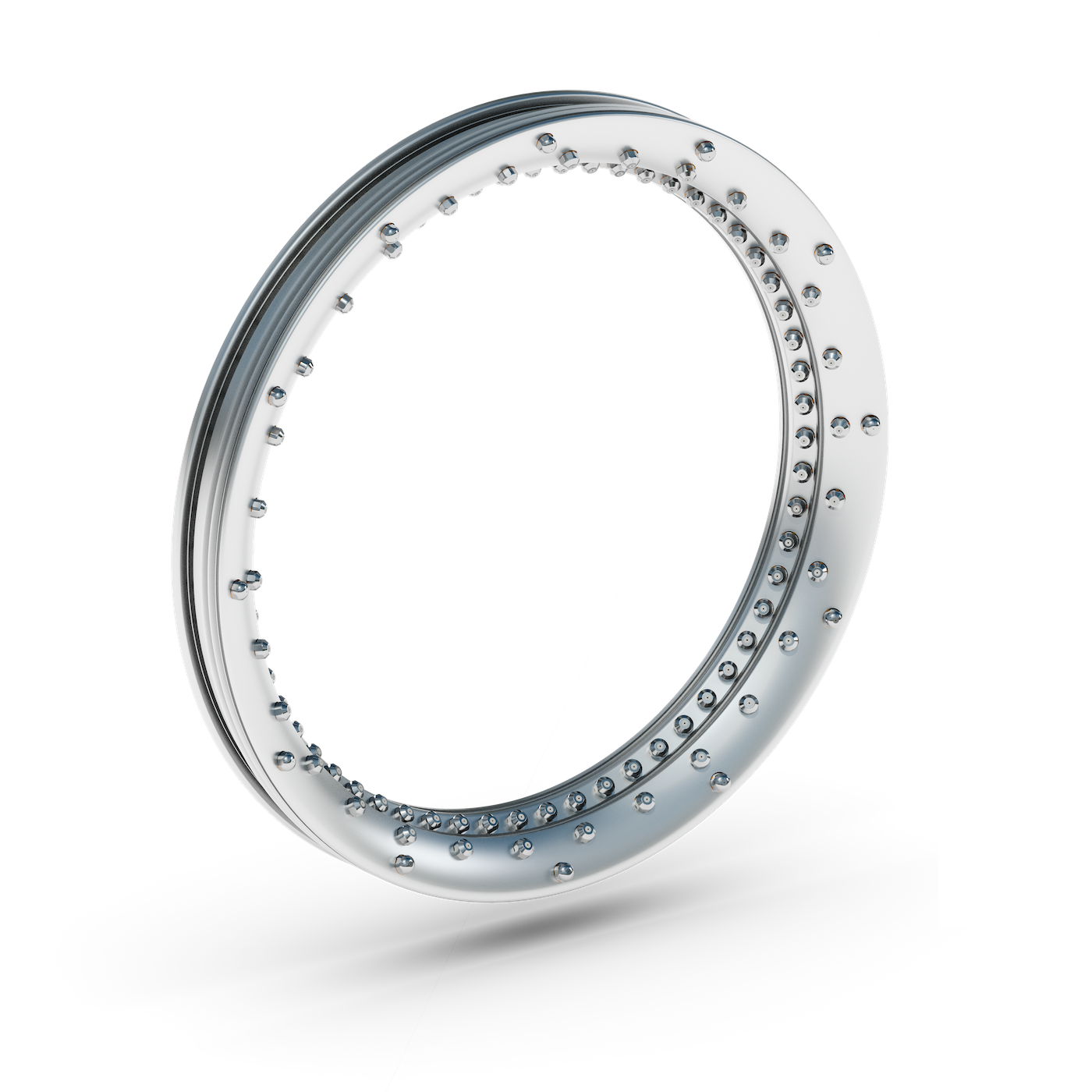

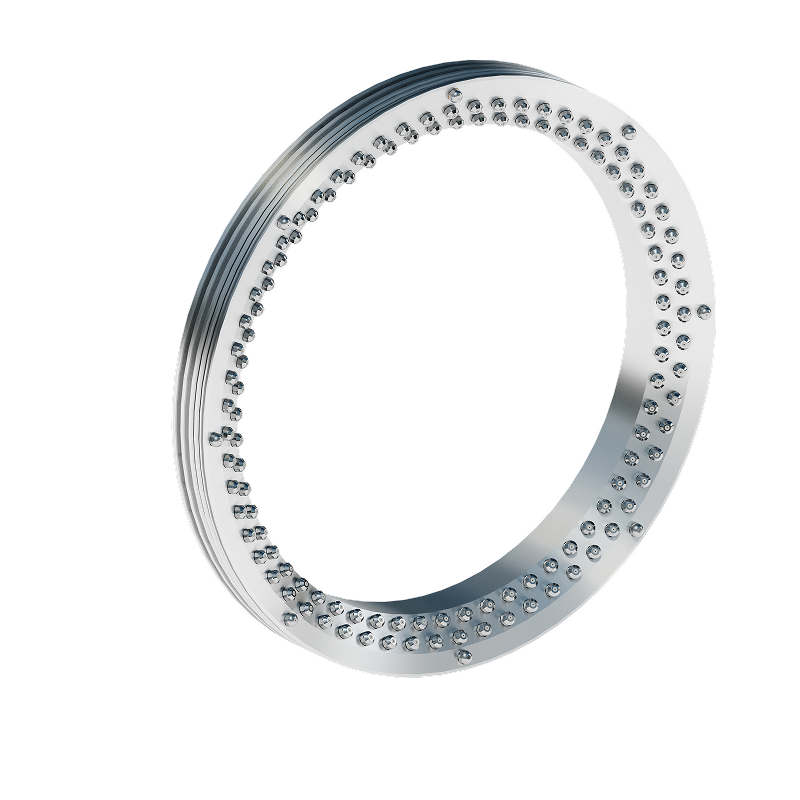

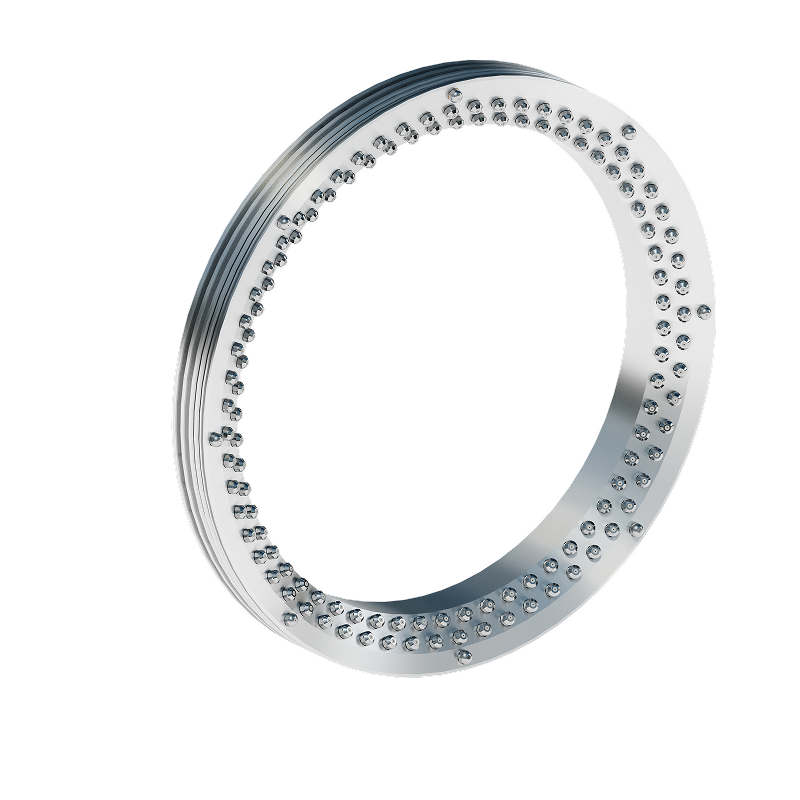

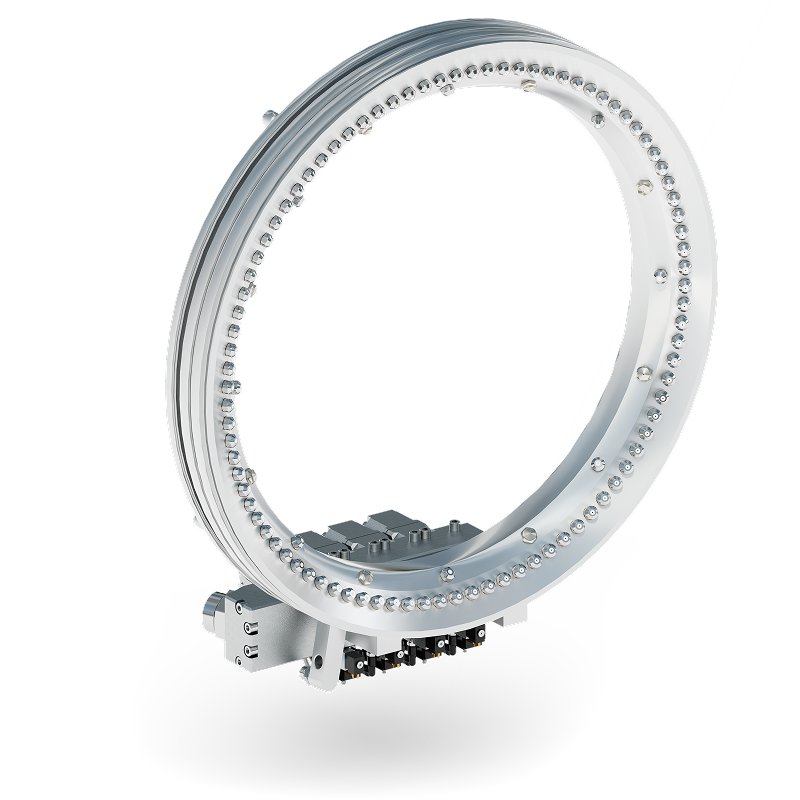

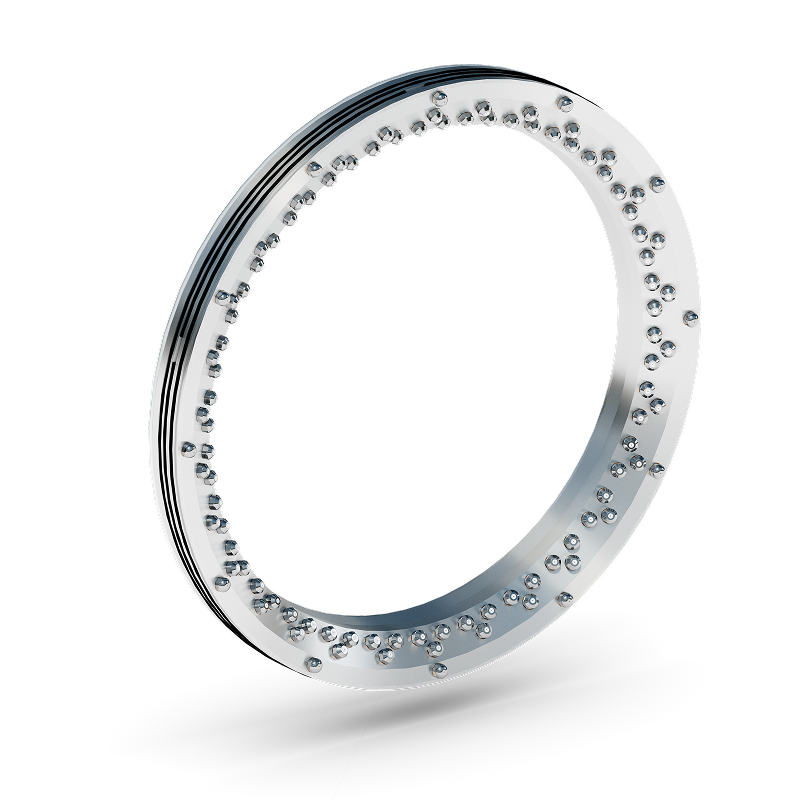

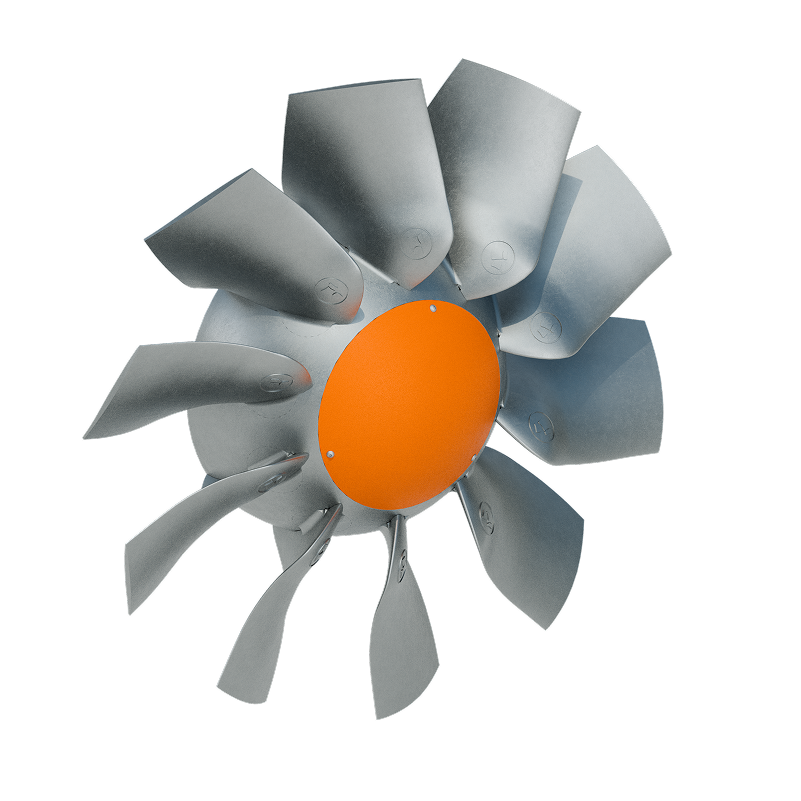

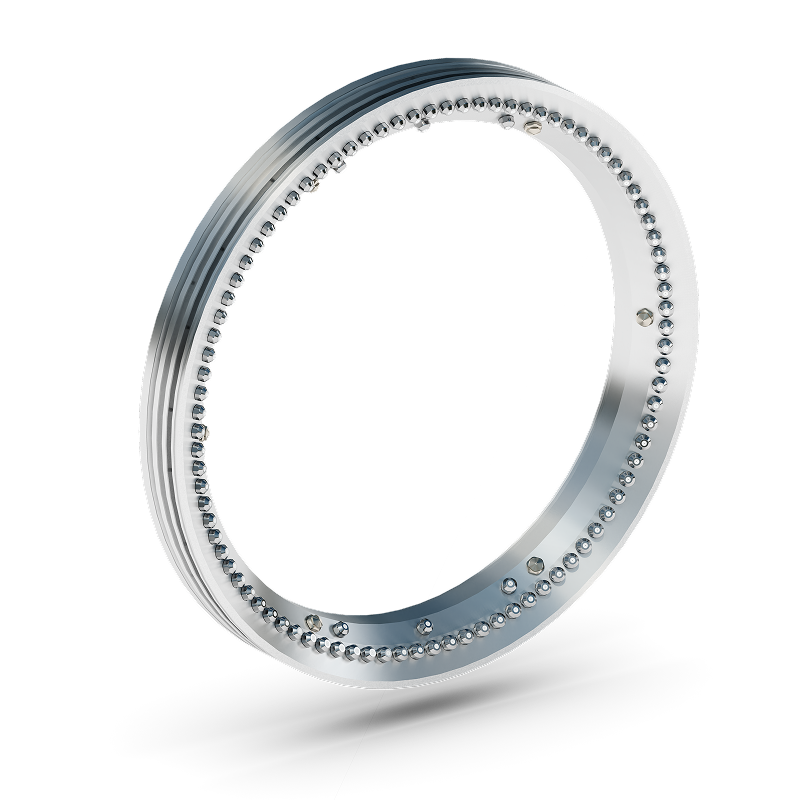

Water ring

The design of the ring used in the 600M enables fast and efficient snowmaking. The cannon can produce as much as 83 m³ of high-quality technical snow per hour.

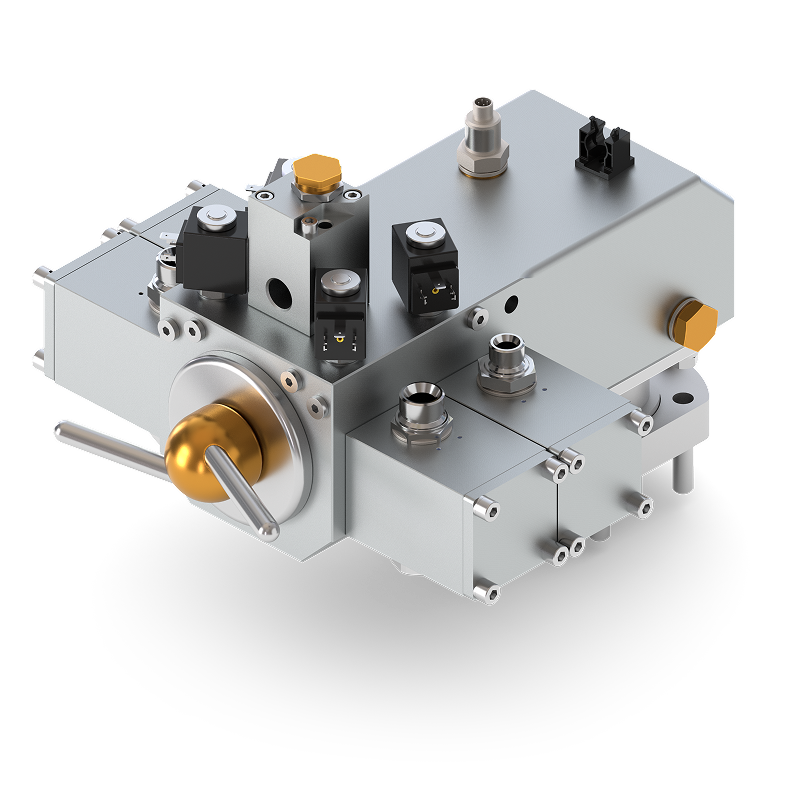

Water complex

The 600M was designed to make its operation fast, simple and extremely intuitive. A characteristic element of the cannon is the water unit, the design of which significantly improves the ergonomics of the entire device. Thanks to this design, all 600M operations can be performed in one place.

Water ring

The design of the ring mounted 900MN cannon allows to increase snow production capacity to 112 m³ per hour, while reducing electricity consumption. This makes this model an ideal combination of high efficiency and economical energy management.

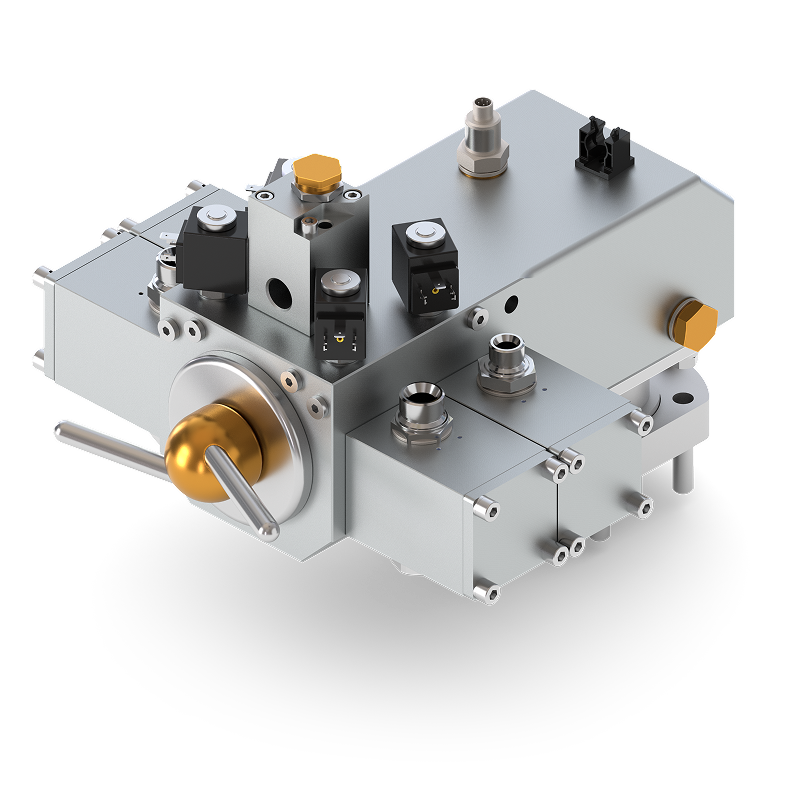

Hydraulic water unit

The 900MN cannon consumes less energy than other cannons of this class available on the market. This is due, among other things, to an innovative hydraulic control system, which replaces the traditional electric system. Hydraulic control of oscillation and hydroswitches also ensures trouble-free operation of the cannon in all conditions.

Control panel

The 900MN snow cannon is distinguished by an intuitive control system that significantly simplifies operation.

Fan

This model is equipped with a fan with an efficient impeller with a unique shape, inspired by owl wings. Its design allows to significantly reduce the noise level generated by the device, which positively affects the environment.

Slotted filter

We design our devices so that their operation is simple and intuitive. The cleaning process of the slotted filter is extremely easy – just rinse it under running water. Equally simple is the installation and removal of ceramic nozzles. These are examples of simplification of maintenance activities that save time.

Hydraulic water unit

The 900A cannon stands out in its class for its high electricity savings. This is due, among other things, to the innovative hydraulic control system, which replaced the traditional electric system. Hydraulic control of oscillation, tube lifting and hydro-valves further guarantees trouble-free operation of the cannon in all conditions.

Water ring

The design of the ring mounted in the 900A automatic snow cannon allows to increase snow production capacity to 112 m³ per hour, while reducing electricity consumption.

Fan

The fan incorporated into the body of the 900H model is a continuation of the design developed for the 700-series cannons. The aluminum rotor and optimized blade shape allowed to reduce the noise level and increase the efficiency of the fan system compared to the previous, already highly efficient version used in the 900A model.

Valve system

The solution developed by SUPERSNOW’s engineering team eliminates the need for water discharge through the steam traps during machine operation. The water discharge only takes place when the machine is started and stopped. At other times, the excess water is blown by compressed air through the water nozzles, where it turns into snow, preventing the formation of ice around the cannon.

Fan

The fan incorporated into the body of the 900T model is a continuation of the design developed for the 700 series cannons. The aluminum rotor and optimized shape of the blades made it possible to reduce the noise level and increase the efficiency of the fan system compared to the previous, already highly efficient version used in the 900A model.

Water ring

The air from the compressor is cooled as it passes through a heat exchanger built into the water-air ring. This solution significantly increases the efficiency of the nucleation system by increasing snow production, especially at marginal temperatures.

Service position

The 900T cannon is designed for convenient servicing. Its lowering does not require the disconnection of electrical or hydraulic lines, allowing for easy inspection and testing without having to lift the unit again.

11.08 l/s

The 900T is our top-of-the-line cannon, designed for intensive snow production.

Its high flow rate (up to 11 l/s) and excellent snow quality make it an ideal choice for resorts that need to make the most of every weather window.

Standard working position

The 900H is the answer to the transformation of the snowmaking market, where maximum performance and operation in ever-shorter weather windows are becoming crucial. This mobile snow cannon offers top performance, providing full mobility on the slopes.

11.08 l/s

The 900H is our top-of-the-line cannon, designed for intensive snow production.

Its high flow rate (up to 11 l/s) and excellent snow quality make it an ideal choice for resorts that need to make the most of every weather window.

Slotted filter

Service is quick and easy: the slotted filter simply needs to be rinsed under running water, and the removal and installation of ceramic nozzles is intuitive, reducing downtime.

Water ring

The ring with 90 water nozzles and 12 nucleation nozzles provides up to 83 m³ of snow per hour. The ring’s design benefits energy efficiency – high production at a low energy cost per m³.

Hydraulic water unit

The 700ASE cannon stands out in its class for its high electricity savings. This is due, among other things, to the innovative hydraulic control system, which replaced the traditional electric system. Hydraulic control of oscillation, tube lifting and hydros valves also guarantees trouble-free operation of the cannon in all conditions.

Meteo station

The 700ASE cannon is fully automated, allowing remote control and monitoring of the snow production process. The device automatically adjusts operating parameters to changing weather conditions, ensuring optimal performance with minimal energy consumption.

Inverter

The design of the 700S is based on proven, top-quality components. The key component of the SUPERSILENT version – the inverter – can operate at temperatures down to -40°C, and its IP66 rating confirms its high resistance to water and dirt. This makes the device perfect for the most demanding conditions , maintaining efficient snow production with low noise levels.

Fan

The Cannon 700S in silent mode emits sound power of only 91.8 dB, which can be compared to the noise generated by a hair dryer. Such a low sound emission level is due to the new design of the nucleation nozzles, which made it possible to reduce the pressure in the nucleation system by 2 bars, and an inverter that reduces the fan speed.

Fan

The finely tuned geometry of the fan channel and impeller minimizes resistance to air flow through the cannon tube. The use of rotor blades with increased stiffness additionally reduces noise and increases fan efficiency.

Mesh filter

We design our devices so that their operation is simple and intuitive. The cleaning process of the mesh filter is extremely easy – just rinse it under running water. Equally simple is the installation and removal of ceramic nozzles. These are examples of simplification of maintenance activities that save time.

Water ring

The ring in the 700H model is equipped with 96 water nozzles and 6 nucleation nozzles, allowing it to achieve a capacity of 88 m³ of snow per hour. Its design promotes electricity savings, making this model a perfect combination of high performance and energy efficiency.

Hybrid water unit

The design of the hybrid water unit reduces energy consumption by using thermal energy and water pressure to control the valves. This solution ensures efficient and environmentally friendly operation while meeting the highest energy standards.

TwinC® nozzle

The innovative ceramic insert, implemented in TwinC® SUPERSNOW nozzles, is characterized by high resistance to abrasion caused by the flow of contaminated water. It ensures that the flow of liquid is properly directed, guaranteeing that the correct angle of spray is maintained and that the droplet size is optimized, providing optimum cannon performance for years to come.

Nucleation nozzle

The design of the nucleation nozzle makes it possible to achieve optimum performance of the nucleation mixture while significantly reducing the pressure and amount of compressed air. As a result, the power of the compressor has been reduced from 4 to 1.5 kW without sacrificing performance.