Systemsand design

SUPERSNOW snowmaking systems are a complete technical infrastructure including pumping stations, pipelines, power supply, automation and snowmaking equipment necessary for the operational operation of a ski resort. Thanks to the individual design and integration of all components, the system ensures controlled and efficient production of technical snow in all conditions, adapted to the specifics of the slope and ski resort.

Systemsand design

SUPERSNOW snowmaking systems are a complete technical infrastructure including pumping stations, pipelines, power, automation and snowmaking equipment necessary for the operational operation of a ski resort. Through customized design and integration of all components, the system ensures controlled and efficient production of technical snow under all conditions.

SUPERSNOW > Systems

SUPERSNOW snowmaking systemsComplete solutions for ski resorts

Complete snowmaking system - from design to automation

SUPERSNOW snowmaking systems are a complete technical infrastructure including pumping stations, pipelines, automation, power supply, and snow cannons and lances. They form an integrated solution for efficient technical snow production regardless of weather conditions.

These systems ensure the continuity of ski resorts’ operations, guaranteeing stable snow conditions, earlier season opening and season extension. With a customized design approach, SUPERSNOW creates installations tailored to each terrain and resort specifics.

Elements of a complete snowmaking system

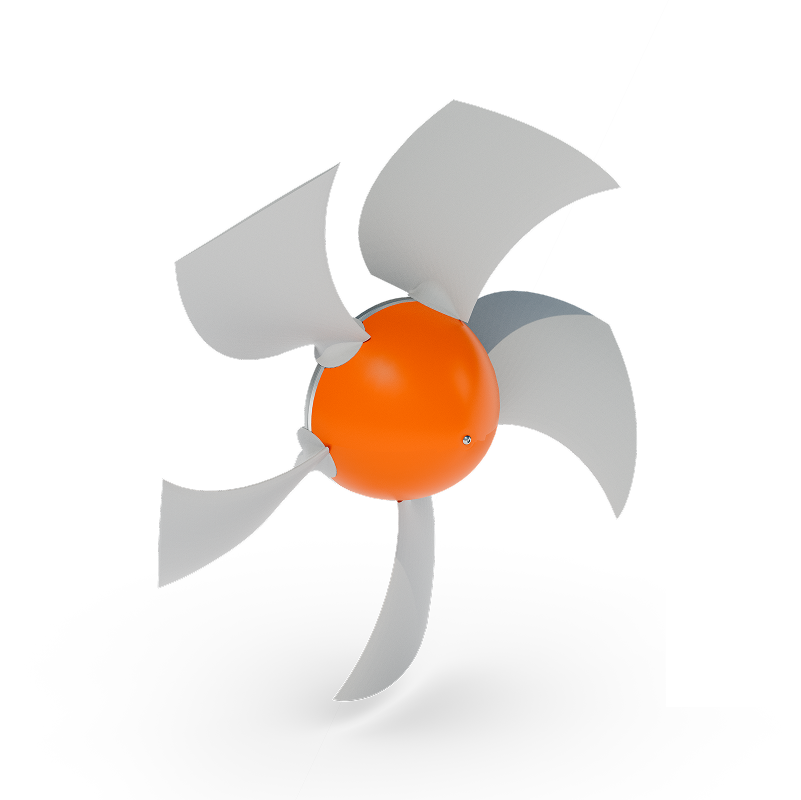

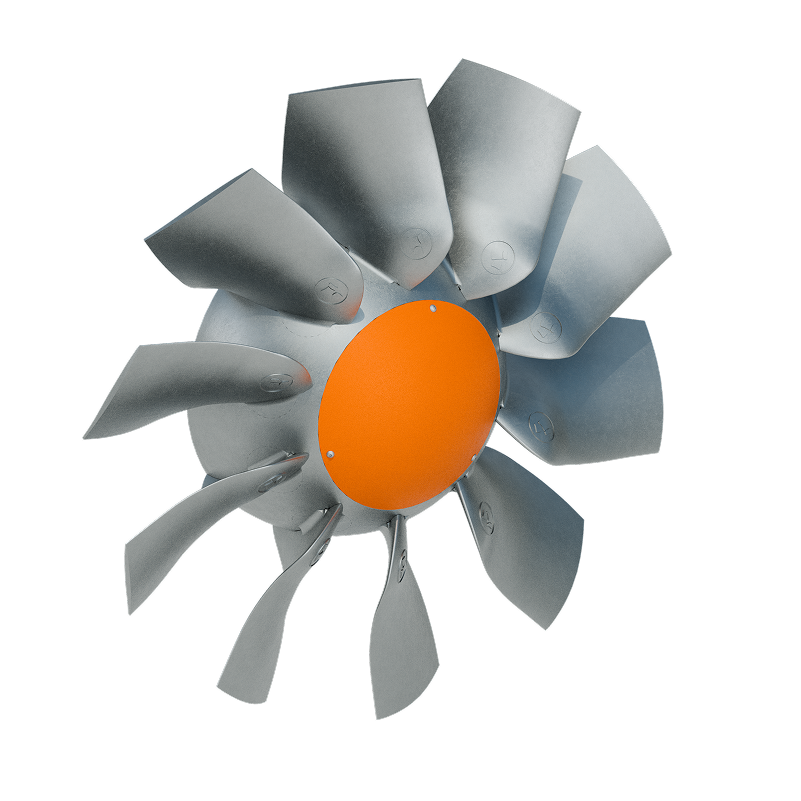

- Snow cannons

- Lance

- Pipelines

- Pump stations

- Retention tanks

- Mobile pumping stations:

- MP200

- MP500

- Cooling towers

- Filtration and air systems

- Electrical networks

- Technical wells

- SNOWMATIC central management system

- SUPERSNOW mobile app

Design of snowmaking systems

Designing a SUPERSNOW snowmaking system is a technical and analytical process, led by a team of engineers specializing in hydraulics, automation and electrical engineering. Each design is tailored to local conditions, terrain and the resort’s operational goals.

SUPERSNOW engineers develop the hydraulic and electrical schematic, select fittings, pumps and system communications. Snowmaking scenarios are defined for each project, as well as how the entire system works.

Design process

1. analysis and site visit – data collection and site assessment.

2. technical design and budget – preparation of concept and cost proposal.

3. implementation –implementation of snowmaking system according to customer requirements.

SUPERSNOW offers flexible solutions with the possibility of future expansion. When designing the system, engineers select pumps with a power reserve, allowing capacity to be increased without rebuilding the infrastructure.

Storage tanks - a source of efficiency and independence

Retention reservoirs are a key component of the snowmaking system. They allow water to be collected and reused in accordance with the principles of sustainable water management. SUPERSNOW designs reservoirs with optimal capacity, tailored to the demand of the resort and local conditions.

SUPERSNOW reservoirs are sealed with Firestone’s EPDM geomembrane, making them extremely resistant to all external factors. Each SUPERSNOW retention tank is fenced and equipped with a special aeration system to prevent water from freezing.

SUPERSNOW retention reservoir – in addition to providing the ski station with an adequate amount of water, has a positive impact on the environment – reducing or eliminating the disruption of the water cycle in nature.

The freezing of water in the reservoir adversely affects the operation of the snowmaking system. This is because the ice that forms on the surface of the reservoir is an insulator and prevents the water underneath from cooling down. The optimal water temperature for snowmaking is 0-2 °C. Warm water under the surface of the ice reduces the possibility of snow production by up to several tens of percent.

We have developed a method of cooling the water and preventing the ice sheet from freezing by aerating the tank. Air is forced through a system of pipes into the tank. This sets the water in motion. On the surface, it does not freeze, and the rippling of the water surface increases the contact area with cold air. As a result, more heat escapes into the atmosphere.

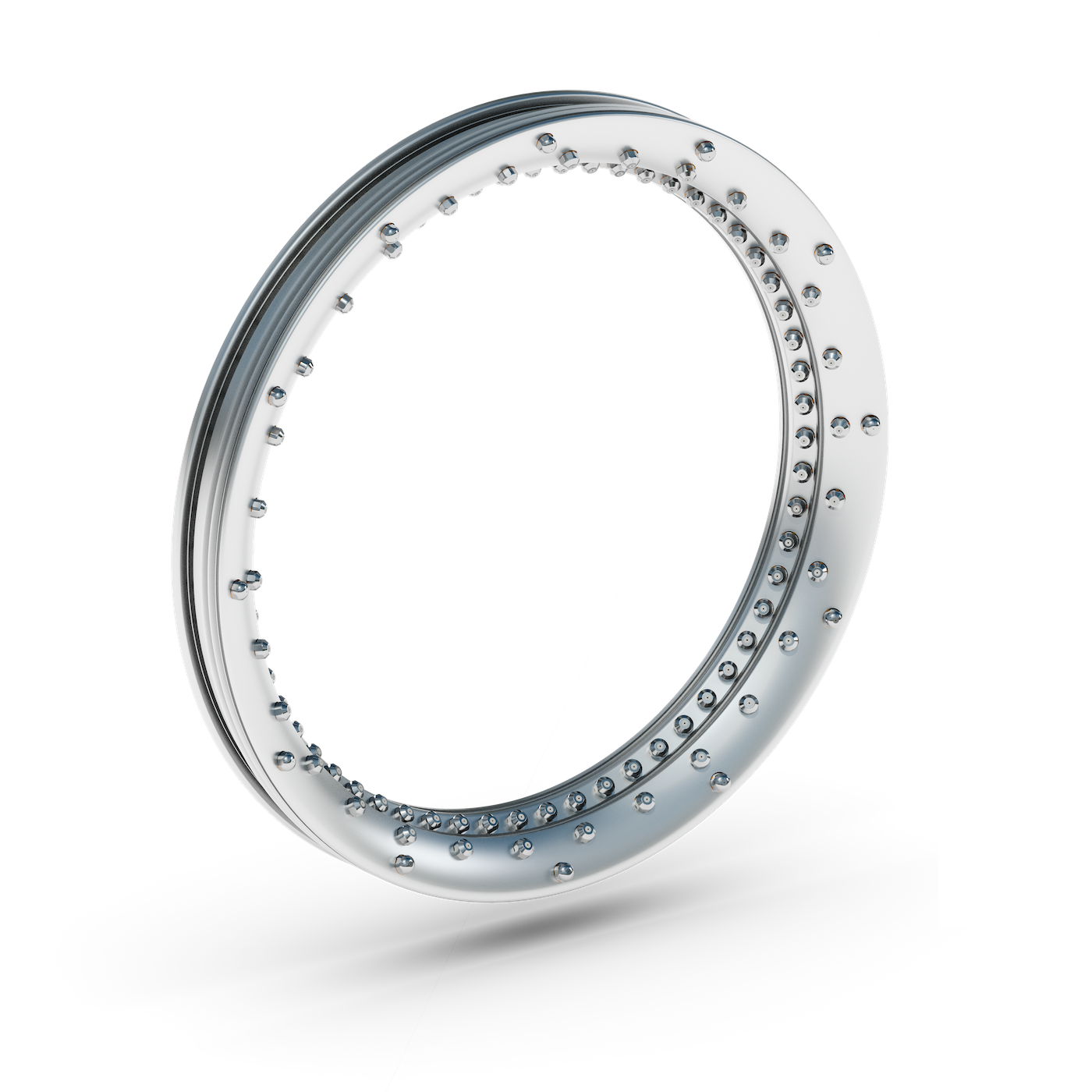

Pipelines and hydraulic infrastructure

We install two types of pipelines in our systems:

- Alvenius Snowline steel pipelines

- TRM ductile iron pipelines, Ductus

Alvenius Snowline

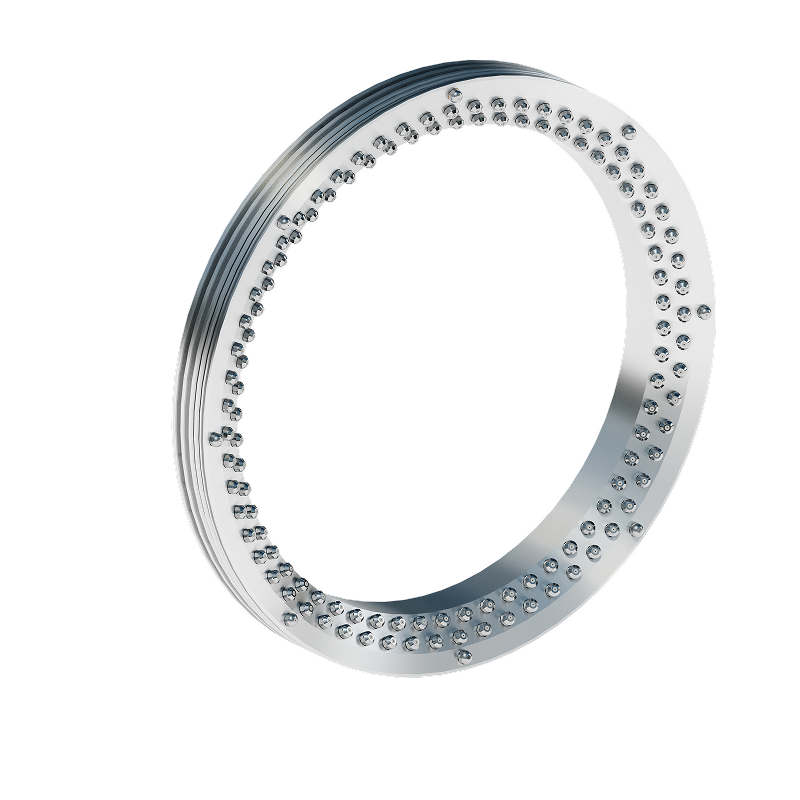

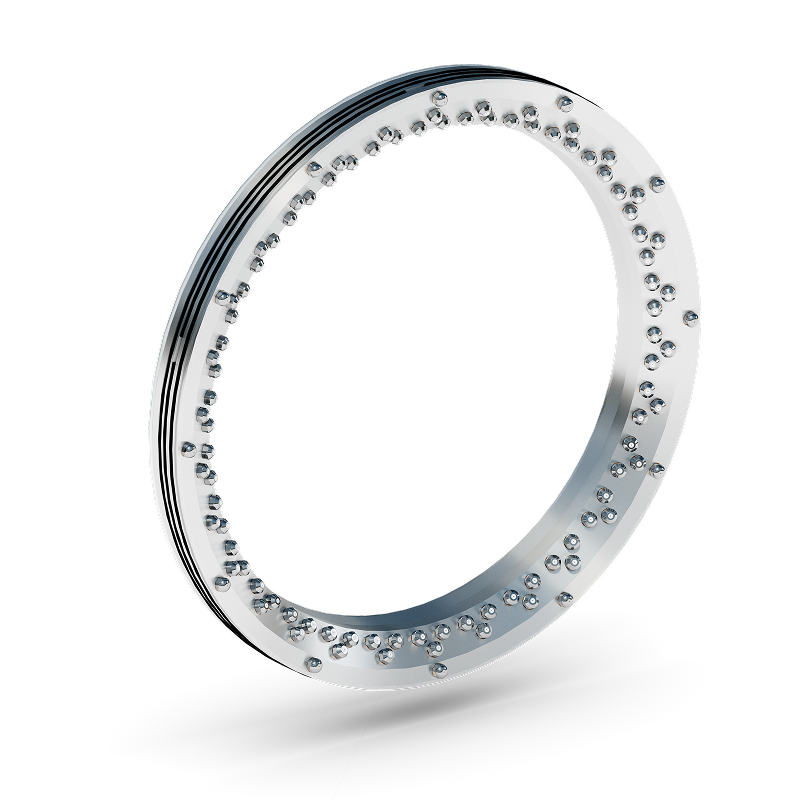

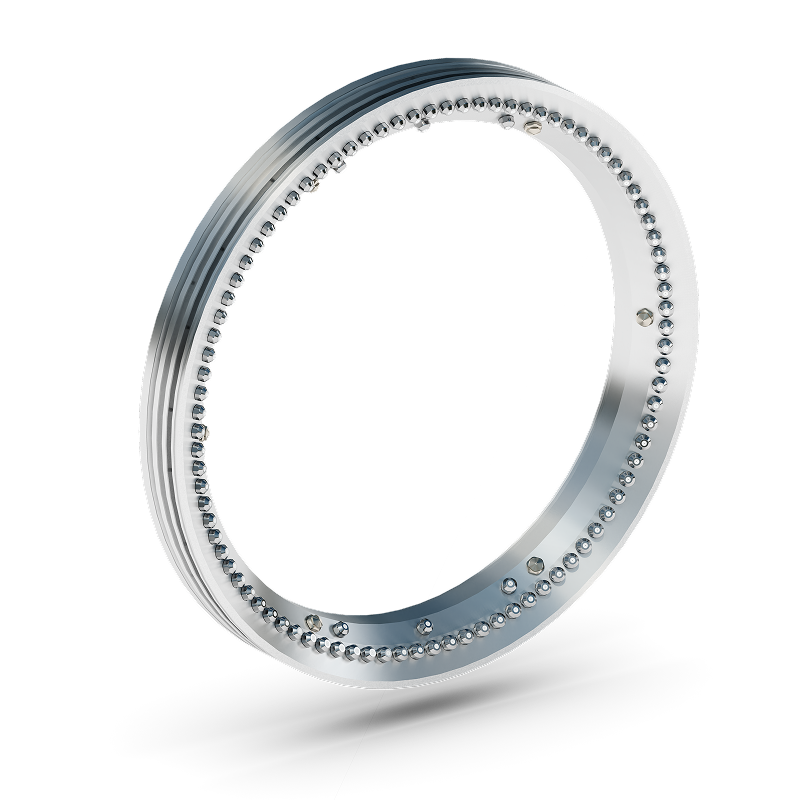

Alvenius Snowline steel pipes are designed specifically for technical snowmaking. They are divided into sections of 5.8 meters in length. The sections are bolted together with Victaulic fittings.

Each component is subjected to hydrostatic testing at a pressure 50% above the usable pressure. Pipes, inside and out, are protected by thermal electroplating, carried out at Alvenius’ factories.

The great advantage of the system is the low weight of the components. A 5.8-meter-long pipe with a diameter of 139 mm weighs just 54 kg.

Cast iron pipelines (TRM, Ductus)

Thanks to the use of magnesium in the smelting process, cast iron retains its durability and gains flexibility. This ideal combination of elasticity and toughness makes ductile iron an excellent material for pressure pipelines. Its characteristics are unique: elasticity comparable to steel, high bending and tensile strength, extraordinary robustness and service life.

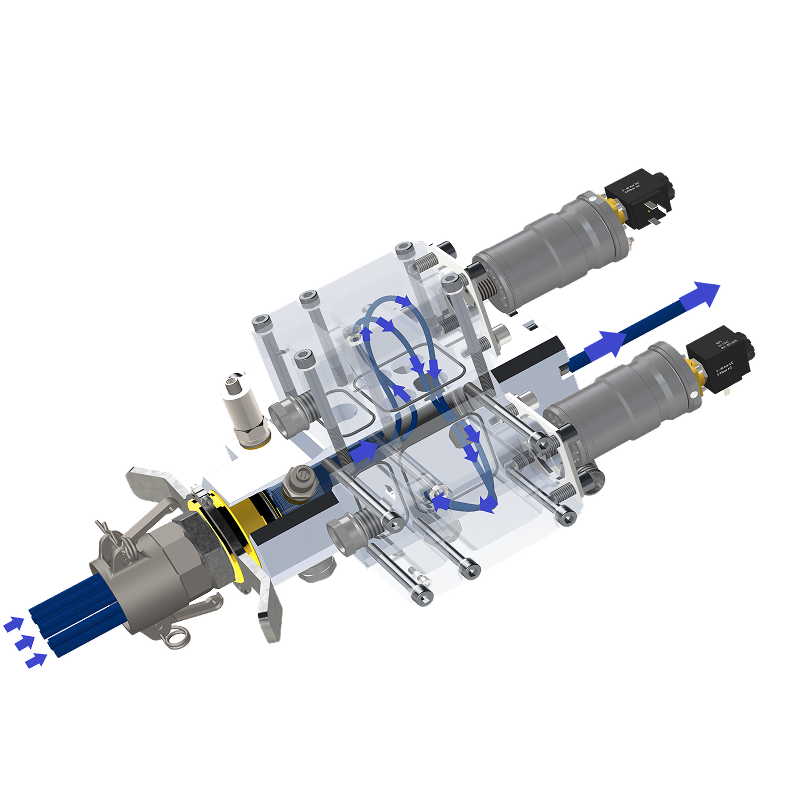

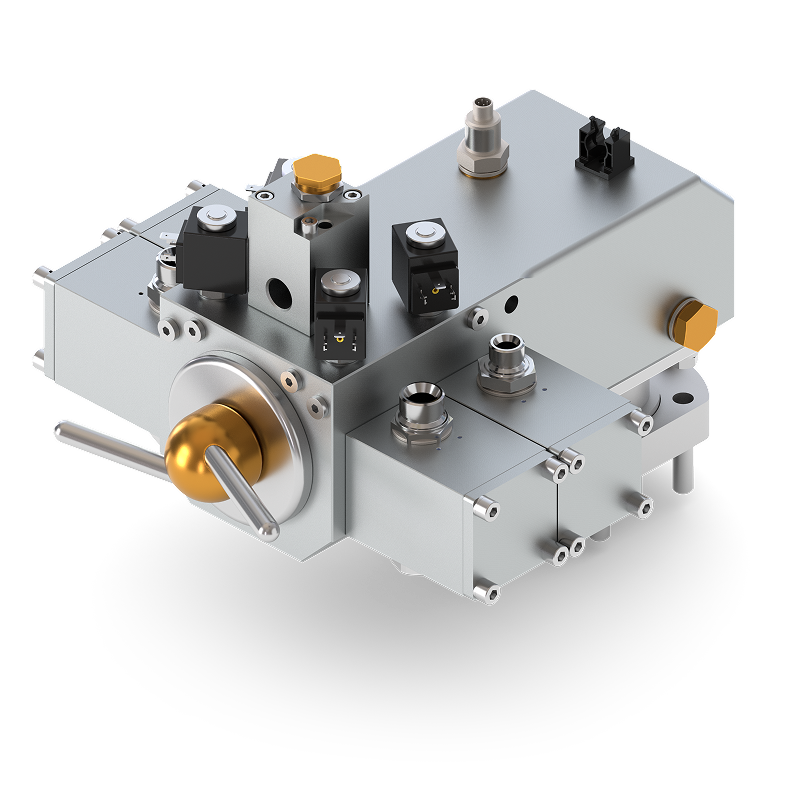

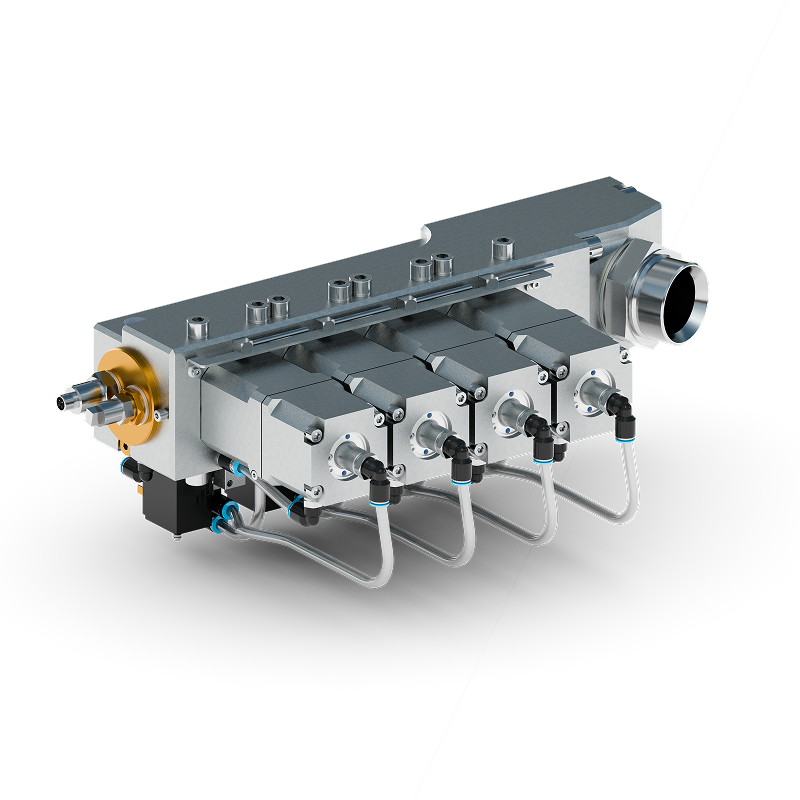

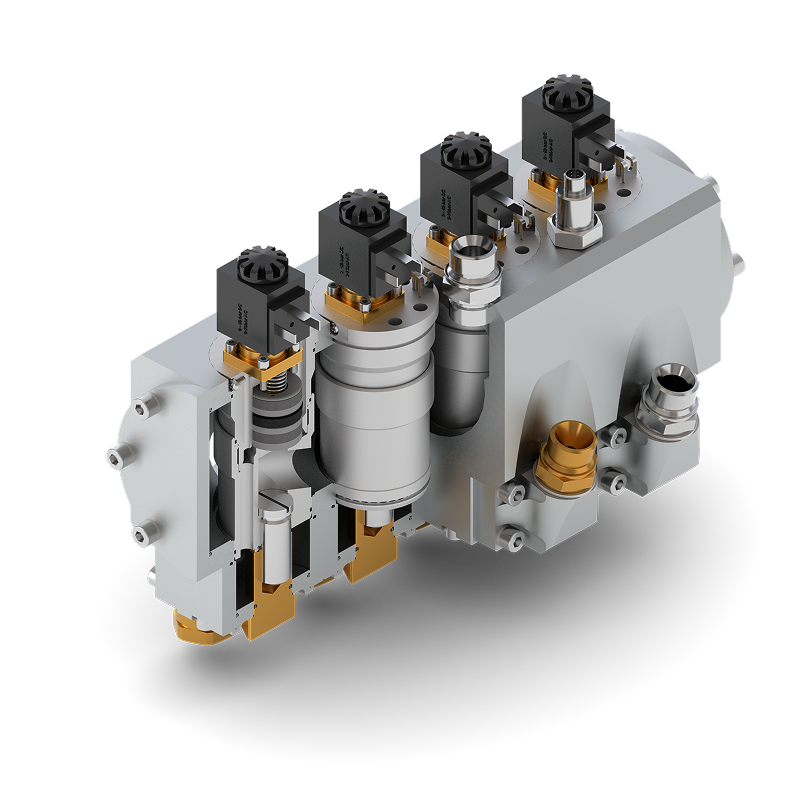

Pump stations and pumping stations SUPERSNOW

Pump stations are the heart of the snowmaking system. They are the ones that deliver high-pressure water to the snow cannons and lances. SUPERSNOW uses top-of-the-line pumps from manufacturers such as Caprari and KSB, with Siemens and Hoyer (Indukta Polska) motors. The pumping stations are designed with a capacity reserve, which makes it possible to expand the system without replacing the entire infrastructure.

Each SUPERSNOW pumping station is designed from scratch and in cooperation with the client. Depending on the client’s requirements, we create and build single-stage pumping stations (high-pressure pumping stations – pumping water from a reservoir or watercourse directly to the slope) and multi-stage pumping stations (systems consisting of a back-pumping station – low-pressure and subsequent pumping stations, whose task is to increase pressure) – for manually controlled, semi-automatic and automatic snowmaking systems.

SUPERSNOW pumping stations are equipped with control panels and special software, allowing central control. We use materials for the pumping stations, supplied by the world’s best manufacturers. Regular maintenance and reliable SUPERSNOW materials guarantee the reliability and highest quality of the system. Most of the materials are in our warehouse, which makes the construction time of the pumping station extremely short.

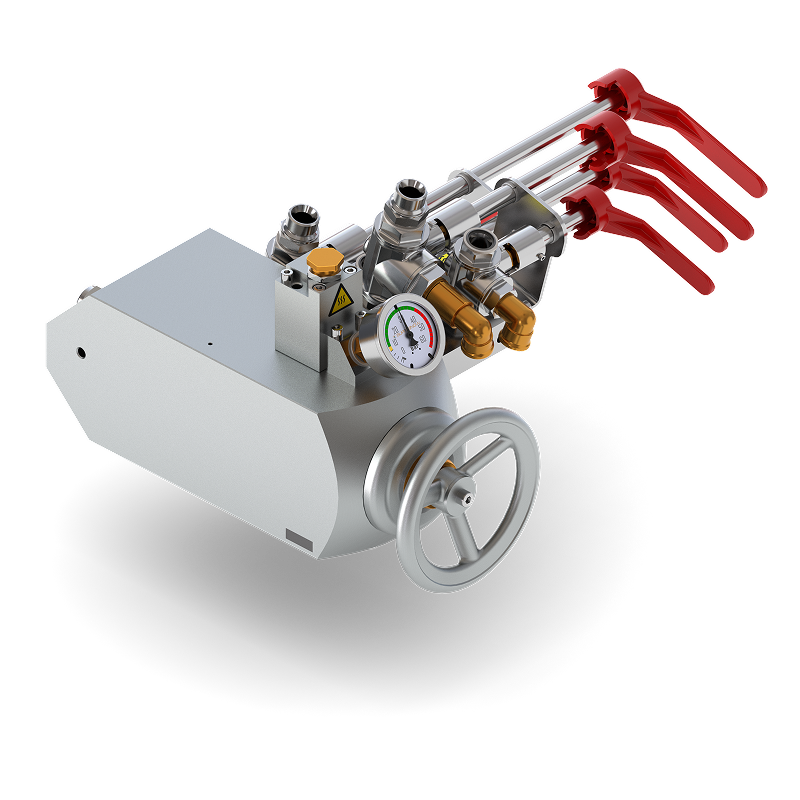

Mobile pumping stations - flexible solutions for any site

Ski resort owners often face the problem of a partial lack of snow in certain areas of the slope. Many times the terrain does not allow the installation of elements of the traditional snowmaking system in places where access is particularly difficult.

In such cases, the SUPERSNOW mobile pump comes to the rescue.

- MP200 – Installed on a wheeled chassis with stabilizing feet, the 15, 22 or 30 kW pump can handle a maximum of 4 snow cannons. In combination with SUPERSNOW mobile snow cannons, it is ideal for cross-country skiing trails. Its small size allows for quick transportation and very easy operation.

- MP500 – This mobile container pumping station functions exactly the same as traditional pumping stations. It works in any snowmaking system. Its small size and low weight mean that it can be placed anywhere, while the installation itself is extremely easy and fast. SUPERSNOW offers pumps from 55 kW to 132 kW as standard. More powerful pumps are available upon individual customer request.

Thanks to their mobility, these devices do not require a construction permit and can be used seasonally in different locations.

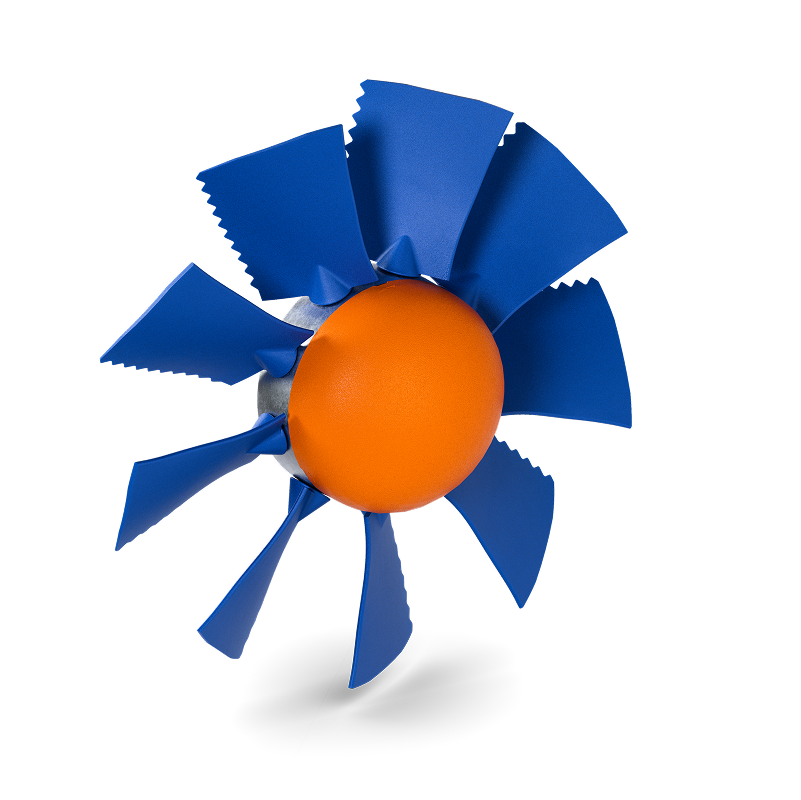

Cooling towers and filtration systems

Cooling towers are responsible for lowering the water temperature, which directly increases the efficiency of technical snow production.

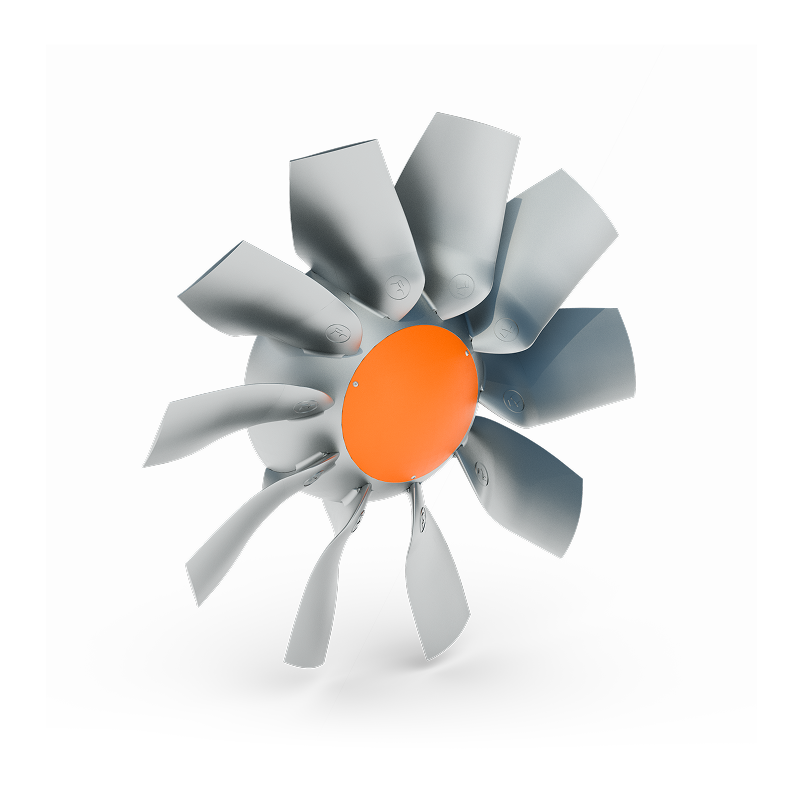

The fan cooling tower, through its activity, cools the water, preparing it, among other things, for transfer to the cannons on the slope. Through its activity the water is cooled and aerated. This increases the efficiency of snowmaking equipment and reduces costs, resulting from energy savings. The cooling towers have a single sequence, consisting of two modules, which are placed on a concrete pool, which is a drip tray for the cooling tower. Under the drip tray is a concrete basin, divided into two parts with hot water from the basin, and chilled water.

Filtration systems, on the other hand, purify the water from contaminants, protecting the snow cannons and other system components. All processes are monitored and integrated with SNOWMATIC software.

Electrical networks and central air system

SUPERSNOW’s Nastok electrical networks provide reliable power to all system equipment.

Central air systems supply compressed air to cannons and lances, which is essential for the nucleation process. Compressors and air systems are designed to provide maximum efficiency with minimum energy consumption.

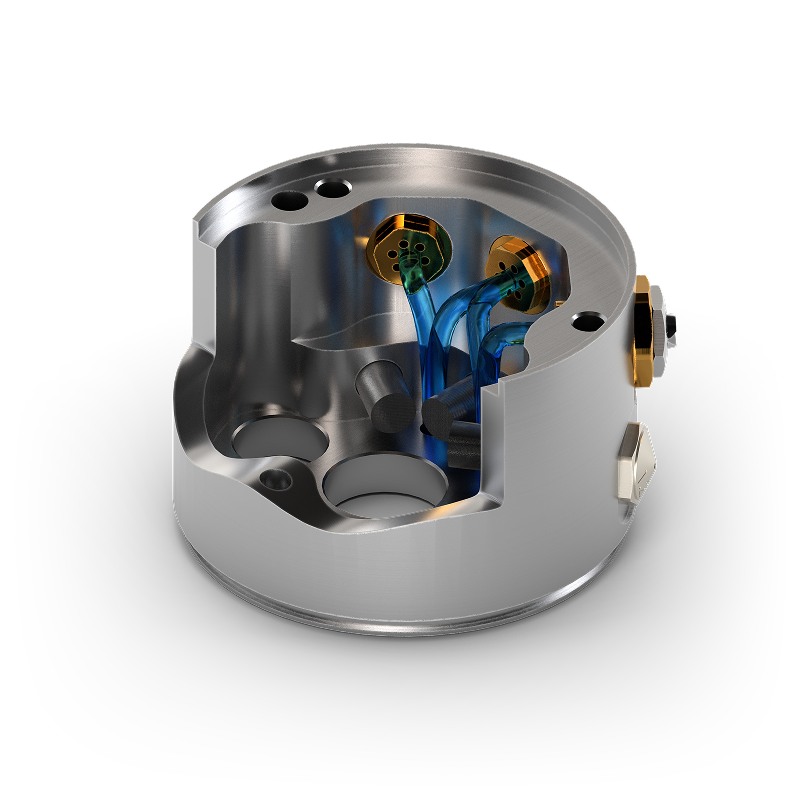

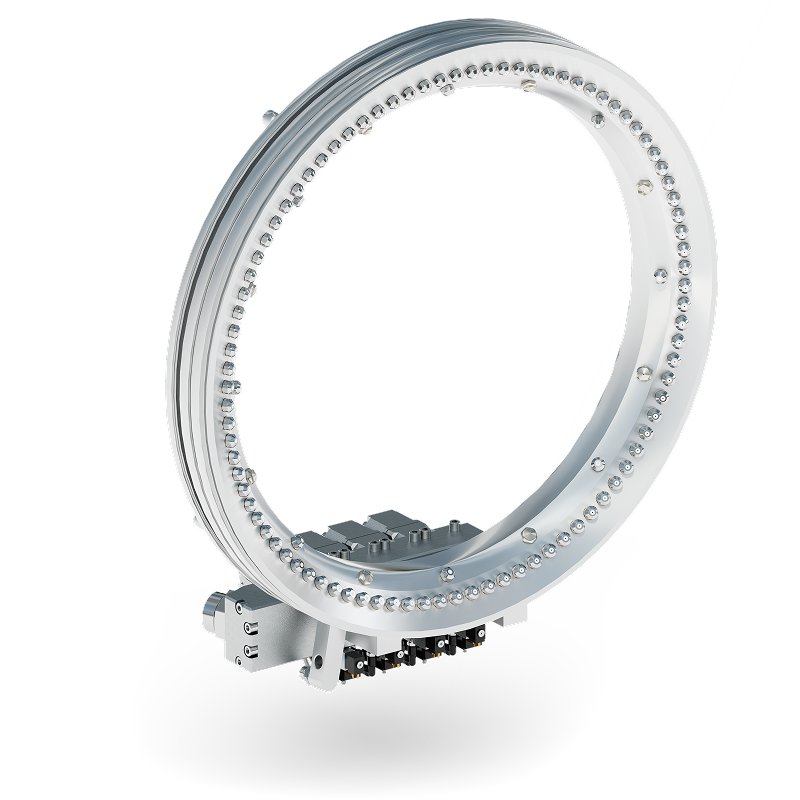

SUPERSNOW technical wells

SUPERSNOW wells are durable, modular solutions for water intake and integration of plumbing, electrical and air systems. Thanks to their well-thought-out design and galvanized components, they ensure quick installation, resistance to field conditions and system longevity.

Two variants are available:

- Universal well – with a large chamber and space for an extension arm T600.

- Compact well – economical version under the boom T400, ideal for narrower routes.

SUPERSNOW - your partner in building a snowmaking system

With experience and in-house engineering, SUPERSNOW designs, manufactures and implements complete snowmaking systems for the highest efficiency and reliability.

From design to automation, these are solutions created for snow certainty, season stability and maximum efficiency of every drop of water.

Skontaktuj się z naszym zespołem

Nasi doradcy handlowi dostosują ofertę do potrzeb Twojego ośrodka narciarskiego.

Arkadiusz Kitkowski

Polska

woj. dolnośląskie, opolskie, zachodniopomorskie, lubuskie, łódzkie, wielkopolskie, kujawsko-pomorskie

Mateusz Łukaszczyk

Polska

woj. małopolskie, podkarpackie, świętokrzyskie, śląskie